- Homepage

- Materials and their processing

Materials and their processing

We strive to create equipment that not only lasts for many years, but also retains its original strength and beauty throughout its lifetime. That is why we pay special attention to the choice of materials from which it is made, as well as their processing. We are constantly improving our technological processes and use only the highest quality materials to achieve this goal.

Wood

Leber works with larch, pine, spruce, aspen, and robinia—species known for their resilience and natural beauty.

Leber wood is a material born in the heart of Russia - in Siberia.

We carefully match the wood type to your project’s unique requirements.

Wood is the main element of the natural series of equipment inspired by the natural beauty of nature, which creates a harmonious and stimulating environment for play and learning, promoting the physical and emotional development of children.

Leber wood is a material born in the heart of Russia - in Siberia.

We carefully match the wood type to your project’s unique requirements.

Wood is the main element of the natural series of equipment inspired by the natural beauty of nature, which creates a harmonious and stimulating environment for play and learning, promoting the physical and emotional development of children.

Pine

Aspen

Larch

Robinia (acacia)

Glued timber

HPL (High Pressure Laminate) with UV protection

It is not plastic, but a natural material based on thermoactive resins and paper. It is extremely resistant to external influences - impact, moisture, extreme temperatures. HPL-plastic differs from its analogs by high hardness, durability, non-toxicity. HPL reliably protects from ultraviolet rays, which prevents fading and destruction of the material under the influence of the sun. HPL provides a low level of emissions of volatile organic compounds (VOC), which makes it safe and environmentally friendly. It is this material that all the elements that children touch during play are made of. Its durability and resistance to all climatic conditions allow HPL to be used in any region.

HPL-plastic is processed with the help of modern CNC machines. They provide fast, accurate, high-quality processing, cutting, drilling, milling of any level of complexity.

HPL-plastic is processed with the help of modern CNC machines. They provide fast, accurate, high-quality processing, cutting, drilling, milling of any level of complexity.

Palette

Beige

Lime

Orange

Mint

Blue

Oak

Yellow

Graphite

Cream

Photos

Stainless steel

Durable and highly resistant to corrosion, stainless steel stands out for its exceptional strength and longevity. This material resists mechanical damage and can endure harsh environmental conditions with ease. It requires minimal maintenance and is easy to clean, making it ideal for high-use applications. Additionally, stainless steel’s excellent anti-corrosion properties make it suitable for a wide range of climates, providing reliability in various settings.

Photos

Carbon steel

TThe basis for the structural elements of playgrounds. Carbon steel undergoes shot blasting and then receives a specialized Leber Zinc Protection coating, ensuring an ideal base for powder paint. This process allows the steel elements to maintain a polished and aesthetically pleasing appearance, even under extreme temperature changes. Carbon steel's inherent strength and rigidity provide dependable durability, ensuring the playground structures can handle significant loads and frequent use.

Photos

Palette

RAL 1001

Beige

RAL 5015

Sky Blue

RAL 5018

Turquoise Blue

RAL 1003

Signal Yellow

RAL 7016

Anthracite Gray

RAL 8017

Chocolate Brown

RAL 9005

Deep Black

Stainless steel fasteners

Creates strong and durable joints between different components and structures of equipment on playgrounds and sports grounds. Provides stability of playgrounds. It does not have sharp edges, which prevents children's traumatism. Due to high resistance to mechanical stress, stainless fasteners minimize maintenance costs and extend the life of the equipment.

Photo

Moisture-resistant plywood

We use strong and durable birch plywood. Depending on the needs of your project, the thickness of the material can vary from 8 to 24 mm. Plywood is subjected to special treatment to ensure its resistance to moisture. This allows the material to be used in high humidity conditions. We apply designer prints on the plywood, which gives it a stylish and modern look.

Photo

Ropes

We combine ropes from different materials — nylon, polyester, polypropylene and steel. Inside we use aluminum stainless steel sleeves. Such ropes provide high strength and resistance to breakage, while remaining soft and elastic. Aluminum rope fasteners are made from recycled aluminum cans, which significantly reduces energy consumption and waste, making our products even more environmentally friendly.

Photos

Slides

We buy the tall slides in Russia. They are manufactured using the rotomolding method, which ensures high density and quality.

In the low slides we use reliable constructions from Belgium. All slides are made of recycled plastic granules, an environmentally friendly and sustainable material that ensures the longevity and safety of our products. The use of recycled plastic contributes to the preservation of the environment. In addition, we have in-house manufactured slides made of stainless steel and HDPE. These are durable and safe structures, ideal for children's playgrounds.

In the low slides we use reliable constructions from Belgium. All slides are made of recycled plastic granules, an environmentally friendly and sustainable material that ensures the longevity and safety of our products. The use of recycled plastic contributes to the preservation of the environment. In addition, we have in-house manufactured slides made of stainless steel and HDPE. These are durable and safe structures, ideal for children's playgrounds.

Photos

HDPE (High-Density Polyethylene)

High Density Polyethylene (HDPE) is characterized by its strength and resistance to mechanical damage, making it suitable for a variety of structural applications. HDPE retains its properties when exposed to high temperatures, which ensures its durability. The material does not absorb moisture and is not prone to corrosion, making it suitable for use in damp environments. Despite its rigidity and strength, HDPE remains flexible and elastic at different temperatures.

HDPE contains no harmful components and does not emit toxic substances. The material is easily recyclable, which helps to reduce environmental impact and maintain sustainable production.

HDPE contains no harmful components and does not emit toxic substances. The material is easily recyclable, which helps to reduce environmental impact and maintain sustainable production.

Photo

Need the help of an experienced professional?

How can we help you?

Are you looking to incorporate this particular product into your project? Or are you looking for detailed information about the material to help you decide?

We have all the documentation you need! Fill out this form and we will contact you with the information you need.

Application created

A manager will contact you shortly at the number you have provided.

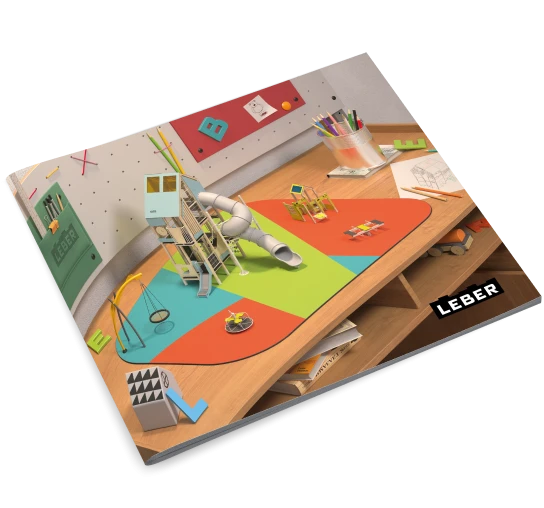

Watch online or order a printed version